Add to Cart

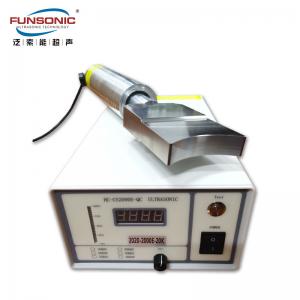

20Khz New Scraping Technology by Ultrasonic Indium Coating Equipment

Description:

Ultrasonic indium coating machine is a device that uses ultrasonic vibration technology to achieve indium material coating. It usually consists of coating tank, ultrasonic vibrator, control system, coating liquid supply system, and support structure components.

Ultrasonic indium coating machines have efficient, uniform, and controllable coating capabilities, and are widely used in the coating needs of electronics, optics, medical and other fields. By adjusting the parameters of ultrasonic vibration and the characteristics of the coating solution, different materials and surfaces can be coated and specific coating requirements can be met.

Parameters:

| Model | FSY-2010-OC |

| Name | 20Khz Ultrasonic External Indium Coating |

| Frequency | 20Khz |

| Power | 300-1500w |

| Temperature Range | 150-400℃ |

| Working Amplitude | 3-20μm |

| Input Voltage | 220V±10%,50/60Hz, 6A |

| Vibrating Head Size | 80*20mm (Curved to fit the external diameter of the tube) |

| Control Mode | Support I/O or 485 communication control, can be integrated with automation operations |

The working principle of the ultrasonic indium coating machine is as follows:

1. Preparation of coating solution: Firstly, a coating solution containing indium material needs to be prepared. This coating solution is usually made by mixing indium powder or indium compounds with solvents. The viscosity and concentration of the coating solution can be adjusted as needed.

2. Ultrasonic vibration: The coating solution is placed in the coating tank of the ultrasonic indium coating machine. Ultrasonic indium coating generates high-frequency ultrasonic vibration, which is transmitted to the coating solution through conduction or radiation.

3. Coating process: When ultrasonic vibration acts on the coating liquid, it causes small eddies and vibrations in the liquid. These eddy currents and vibrations help to evenly disperse the indium material in the coating solution and promote its uniform distribution during the coating process.

4. Coating effect: The indium material in the coating solution will be sprayed onto the target surface in the form of droplets under the action of ultrasonic vibration. Due to the eddy current effect and small vibrations of ultrasound, indium droplets in the coating solution will be uniformly distributed and adhere to the target surface, forming a uniform coating.

20Khz New Scraping Technology by Ultrasonic Indium Coating Equipment