Add to Cart

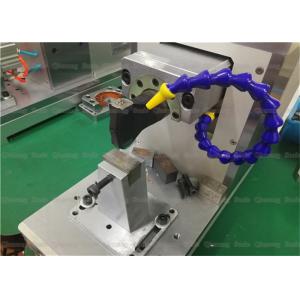

20Khz Ultrasonic Spot Metal Welder for Braided Wire with Special Steel Welding Horn

Description:

Ultrasonic metal welding is a special welding method that uses ultrasonic vibration (frequency over 18 kHz) to connect the same or different metals, semiconductors, plastics, and cermets.

The ultrasonic metal welding process is a process between cold press welding and friction welding that utilizes high density energy generated by high frequency mechanical vibration. The mechanical vibration of the welding head of the ultrasonic metal welding is parallel to the surface of the workpiece. During welding, the static pressure acts perpendicularly on the welding surface through the welding head, and at the same time superimposes the shearing force of the high-frequency vibration. When the shearing force exceeds the elastic limit of the material, the part of the contact surface of the workpiece begins to slip. This shearing force The direction is constantly changed at a frequency of tens of thousands of times per second during the welding process. Breaking and removing dirt on the surface of the workpiece, the surface of the pure metal begins to contact in multiple points. As the high-frequency vibration continues, the contact area of the pure metal expands until it expands into the entire weld zone, and at the same time, atoms are formed on the contact surface. Diffusion, metal recrystallization produces fine grain structure and exhibits cold metal deformation characteristics.

Specifications:

| Item No | QR-D2020A | QR-D2030A | QR-D2050A |

| Power | 2000W | 3000W | 5000W |

| Air Pressure | 0.05-0.9MPa | 0.05-0.9MPa | 0.05-0.9MPa |

| Frequency | 20KHZ | 20KHZ | 20KHZ |

| Voltage | 220V | 220V | 380V |

| Weight of horn | 55KG | 60KG | 88KG |

| Dimension of Horn | 550*280*380mm | 550*280*430mm | 550*380*660mm |

| Generator Size | 540*380*150mm | 540*380*150mm | 540*380*150mm |

common problem:

The welding head will have a certain heat phenomenon during work, which is caused by the mechanical loss of the material itself and the heat conduction of the weldment. Whether the welding hair heat is normal or not, when the load is not loaded (ie, does not touch the workpiece), the ultrasonic wave is continuously emitted for more than half an hour, and the temperature cannot exceed 50-70 ° C. If the heat is severe, it proves that the welding head is damaged or the material is unqualified. replace.

When there is a howling when the welding head is working, the following reasons should be analyzed:

1. Is the mounting screw loose?

2. Does the weld head have cracks?

3. Whether the welding head is in contact with objects that should not be in contact.

Ultrasonic metal welding products:

1. Nickel-metal hydride battery nickel-metal hydride battery nickel mesh and nickel sheet inter-melting

2. Lithium battery, polymer battery copper foil and nickel sheet inter-melting, aluminum foil and aluminum sheet inter-melting

3. The wires are mutually melted and are entangled into one and more fuses.

4. Wire and various electronic components, contacts, connectors and mutual melting

5. Large-scale heat sinks, heat exchange fins, and honeycomb cores of various household appliances and auto accessories

6. Large current contacts such as electromagnetic switches and non-fuse switches, and mutual melting of dissimilar metal sheets

7. Metal tube sealing, cutting can be water, airtight

8. Solar heat absorbing plate, aluminum-plastic composite pipe, and aluminum plate splicing

20Khz Ultrasonic Spot Metal Welder for Braided Wire with Special Steel Welding Horn